We envision a world that runs on bioplastics — where landfills are shrinking and global warming is a thing of the past; where packaging is environmentally friendly and safe, and our oceans are no longer full of waste.

Unfortunately, standing in our way are several major limitations with conventional means of PHA production:

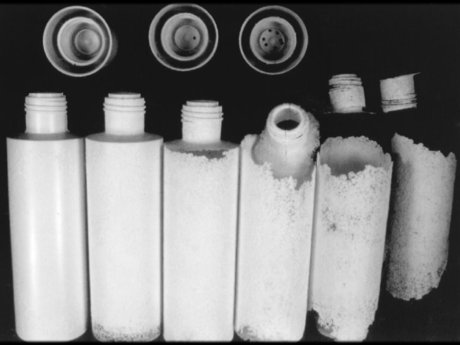

- The granules of plastic produced by microbes remain encapsulated within the cell and must be extracted before processing; current recovery techniques require that carcinogenic and toxic solvents be used to quickly rupture the cell wall and release the plastic.

- Current methods of producing co-polymers are inefficient and resort to a costly technique known as substrate switching.

- The current yield of desirable monomer is low.

Our team envisions a future in which an automated method of PHA production not only eliminates all of the aforementioned issues, but also makes the production process cost-effective. To this end, we have designed a system that we feel can make widespread PHA production a reality within the next two decades.